Cookies help us deliver our services. By using our services, you agree to our use of cookies.

The way from white porcelain to a final product of Reutter

We are pleased to give you a little insight into how our products are manufactured.

Enjoy watching.

Do you have questions? We're here to help. Write us: kundenservice@reutterminiaturen.com

Follow us on Instagram und Facebook for exciting insights, how our products are made and wonderful ideas for your miniature world.

Information

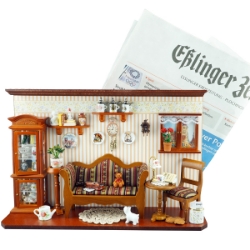

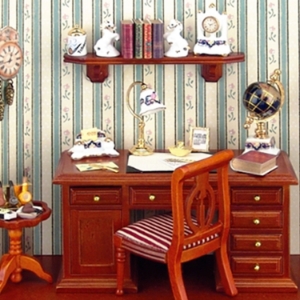

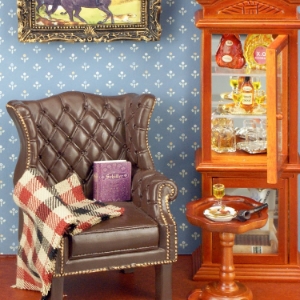

Discover a large collection of high-quality miniatures, miniature furniture and room boxes. The family company Reutter with many years of experience and attention to detail has been producing miniatures since 1948. Welcome to our Onlineshop for private customers! ------ Resellers are welcome to contact: office@reutterminiaturen.com Thank you very much! ------

My account

Customer service

Powered by nopCommerce

Designed by Nop-Templates.com

Copyright © 2026 Reutter Miniatures Onlineshop. All rights reserved.